Due to their special crystal structure, some crystalline materials exhibit a piezoelectric effect which can be used technically for the conversion of mechanical into electrical signals and vice versa.

Principle of action:

- A charge shift of dipole moments in the crystal structure of a piezoelectric material due to external deformation (air pressure fluctuations, surface waves, structure-borne sound) is used to pick up signals of high-frequency oscillations.

- An expansion of the piezo material is caused by an applied alternating electric field, which can generate sound waves.

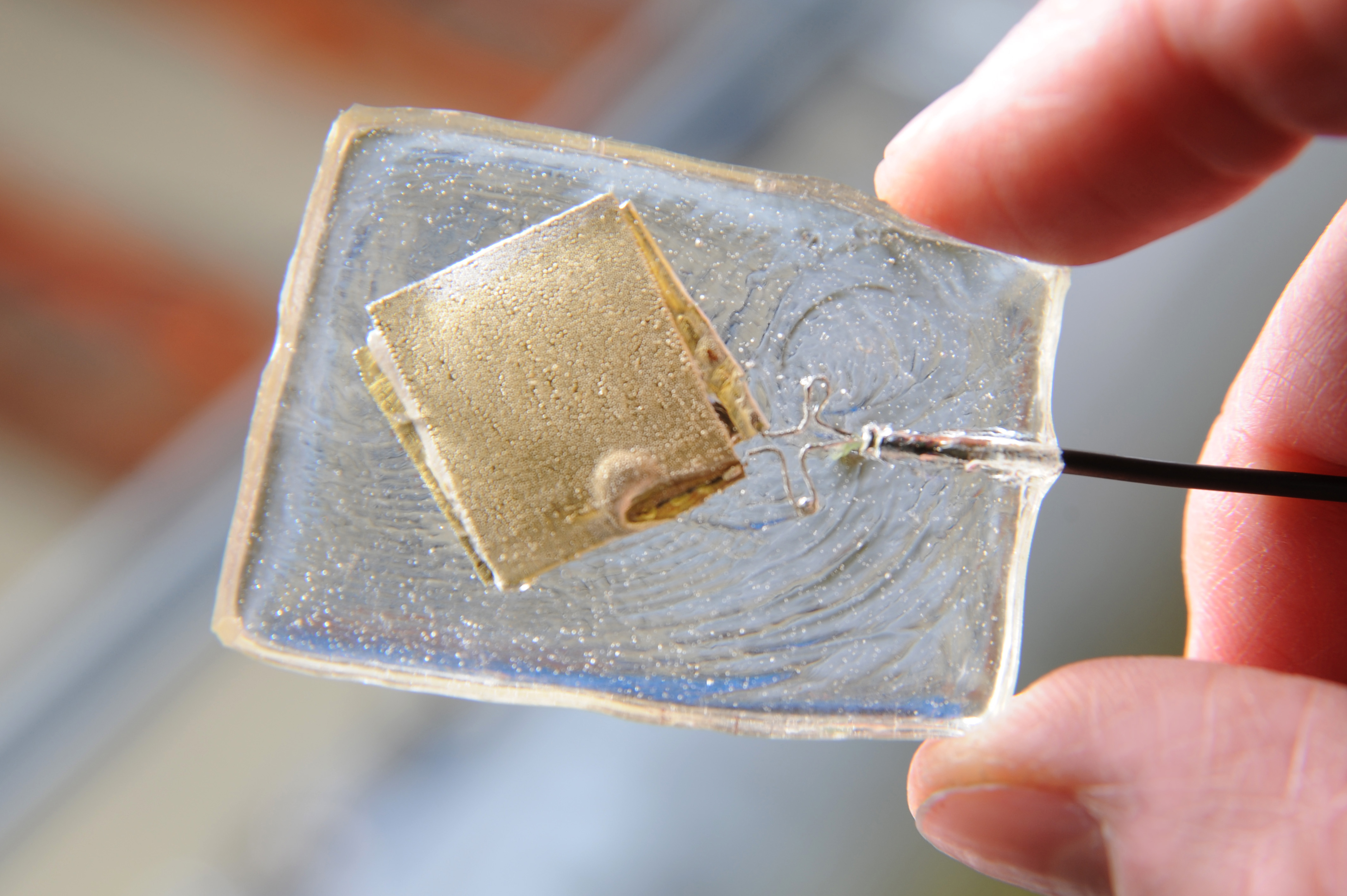

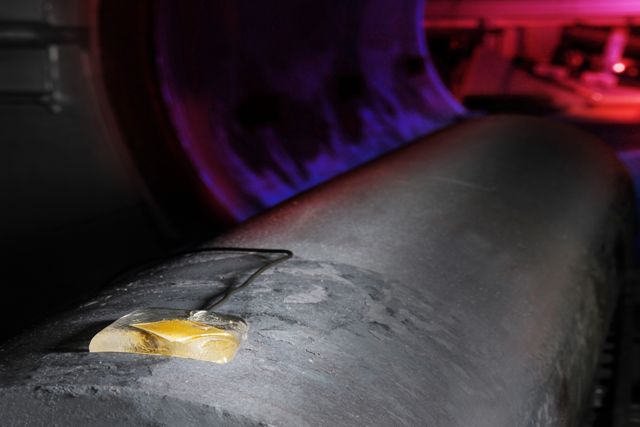

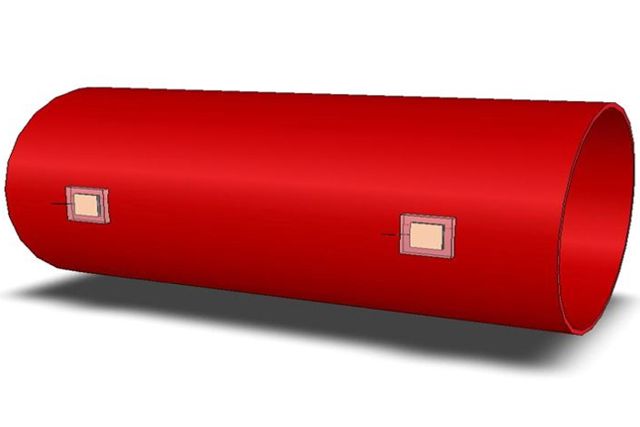

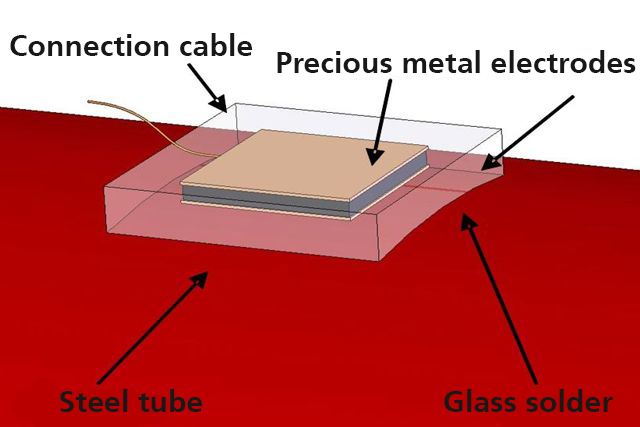

In addition to classical technically used piezoelectrics such as PZT (lead zirconate titanate), which can only be used in low temperature ranges, CeSMA also works with high-temperature resistant piezoelectrics, for example for crack or corrosion detection on hot, heavily loaded components or for ultra-fast (in the ms range) temperature measurement of gases. For high temperature applications (up to 600 °C) single crystals (langasites) are used as an active element. The coupling to the test specimen is carried out by special glass solders, an expertise of the Fraunhofer ISC.