At CeSMA, Smart Materials are used to implement a large number of sensors with which various mechanical properties such as deformations or strains, compression loads or forces and distances or the approximation of a body can be measured. Capacitive, resistive and piezoelectric methods are used as measuring principles. According to the different classes of Smart Materials available, sensors with different measured variables and measuring principles are created.

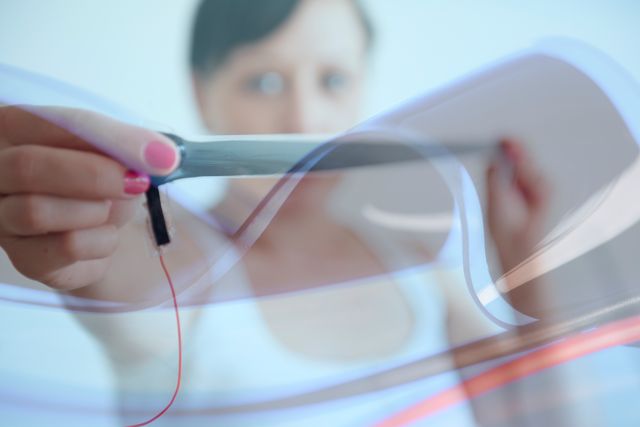

Optical sensors

Optical sensors convert light signals into electrical current. CeSMA develops materials and process technologies to make this conversion as efficient as possible, to increase the functionality and to improve the performance of sensors. This relates in particular to the use of micro-optical components made of hybrid polymers, which can be used to guide, focus and convert light, e.g. on camera sensors.

Sensors for the measurement of mechanical parameters

By adjustment of the material properties and the geometric structures, essential sensor specifications such as measuring range, measuring sensitivity and spatial resolution can be influenced over a wide range. While capacitive and resistive elastomer sensors can naturally detect very high strains of up to about 100 %, piezoelectric sensors cover the range of small strains from 0. 001 to 2 per mill. The measuring range of pressure sensors depends on the selected sensor principle and design and can be set between a few Pa and a few 100 MPa. The usual spatial resolution is in the range of centimeters, but can also be reduced to the millimeter range. The Center Smart Materials and Adaptive Systems already has extensive experience in designing the various sensor types.

Division of mechanical sensors according to measured sensor properties

| Capacitive Elastomer Sensors | Resistive Elastomer Sensors | Piezoelectric Sensors | ||

| Strain sensors | Measuring range Measuring accuracy Dynamics |

0 – ca. 100 % ca. 1 % 0 – a few Hz |

0 – ca. 100 % ca. 10 % 0 – a few Hz |

0 – 0,2 % ca. 0,001 % 0,01 – 106 Hz |

| Compression load sensors | Measuring range Measuring accuracy Dynamics |

0 – 1 MPa ca. 1 % 0 – ca. 10 Hz |

0 – 20 GPa ca. 0,001 % 0,01 – 100 MHz |

|

| Proximity sensors | Measuring range Measuring accuracy Dynamics |

0 – ca. 200 mm ca. 1 % 0 – 1 Hz |