Printable dielectrics and passivation materials based on crosslinkable hybrid polymers

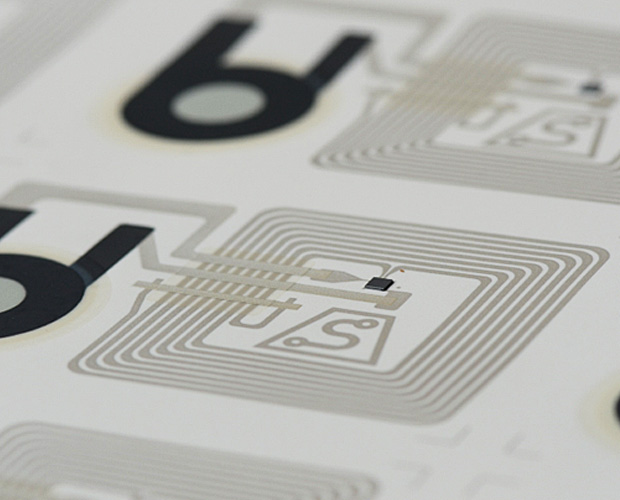

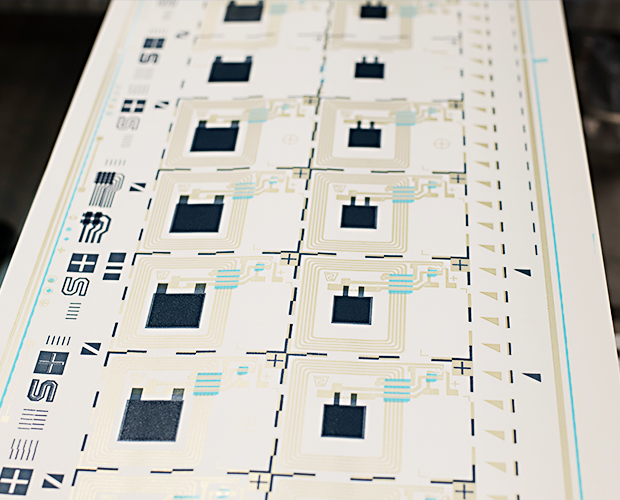

During the last decades, the field of printed electronics was investigated all over the world in order to reduce production costs and integrate electronics on non-conventional substrates. Although it is obvious that printed electronics cannot replace silicon electronics, fields of application emerge starting from simple conductor lines to sensors based on resistive or capacitive measurement set-ups, or for sensing functionalities based on printable smart materials. Nowadays, these printed electronic functionalities are combined with conventional silicon components addressing the field of hybrid electronics.