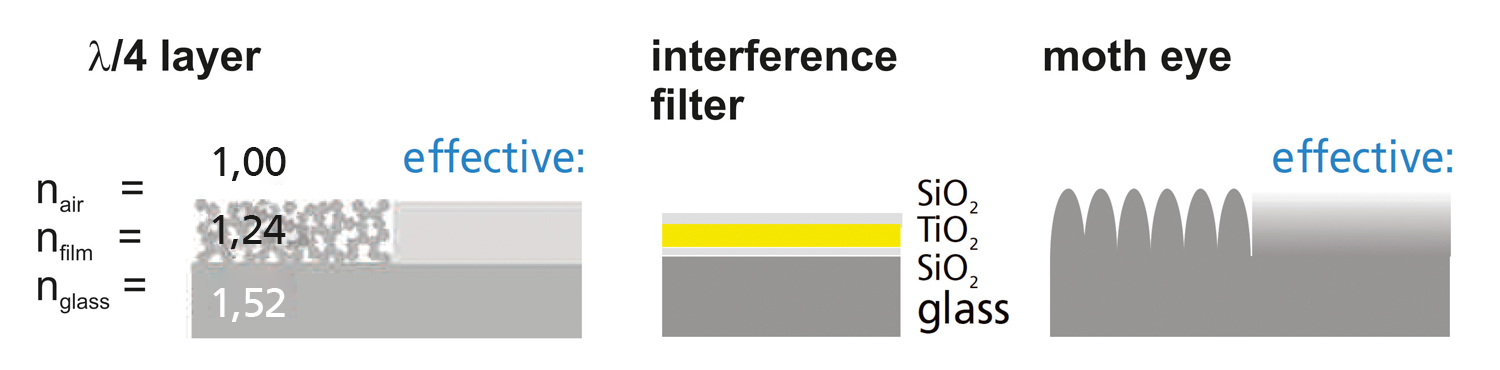

There are basically three different strategies for the antireflection coating of surfaces: With λ/4‑layers, a material is used whose refractive index is between that of the substrate and that of the environment. Such layers are optimally anti-reflective when their thickness equals to ¼ of the wavelength of the incident light. The required refractive indices can only be achieved with porous films of e.g. SiO2 or MgF2.

An antireflective interference surface consists of a sequence of high and low refractive materials, in practice at least three layers are required.

In a so-called moth's eye, nanostructures taper from the substrate to the environment, which results in a continuous refractive index gradient. To avoid optical scattering, the structure size must not exceed 1 µm.

In practice, the respective advantages and disadvantages such as optical performance, mechanical stability and manufacturing costs must be weighed against each other. All described strategies can be realized by wet chemical processes.