Structural health monitoring (condition monitoring) not only serves to increase safety for people and components, but also contributes to minimizing energy and resources by extending service life.

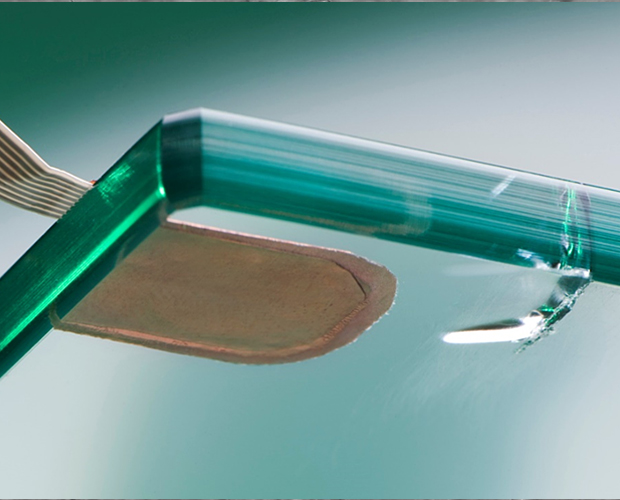

Essential components of monitoring systems are sensors that can be applied or embedded. Piezoelectric sensor elements based on PZT or PVDF can detect natural vibrations of the components and provide information about beginning cracks, delaminations or fastening changes. A few PZT ultrasonic transducers are sufficient to use Lamb waves or acoustic emission to examine large structures for emerging defects with spatial resolution. Rotor blades, aircraft components made of fiber composite materials, metal pipelines or large (composite) glass plates can be continuously monitored with little metrological effort.

Ultra-fast temperature changes can be detected without contact even at temperatures of over 1000° C using special ultrasonic transducers, thus avoiding critical process conditions. Depending on the application, the use of optical, thermal and/or chemical sensors can also be useful, so that multisensor systems can be realized.