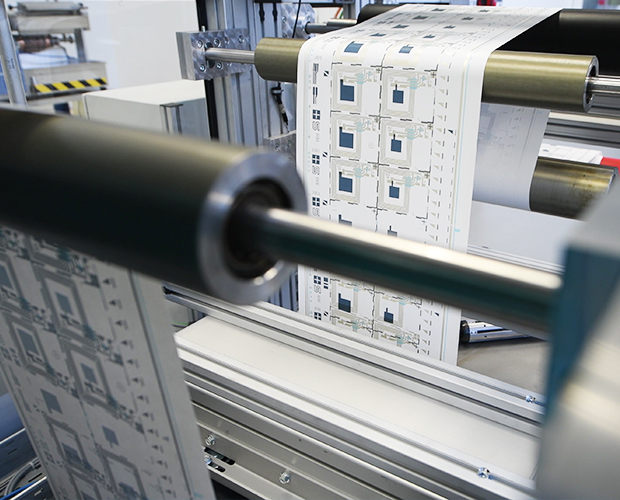

CeSMA uses the roll-to-roll (R2R) coating process in an innovative “Click&Coat” machine from Coatema to produce high-precision printed sensors with high throughput and excellent quality. This technology has already proven itself in successful projects such as C3PO and SuperSmart. The process includes various thermal drying stations and can use either slot die coating or rotary screen printing to apply materials to the substrate.

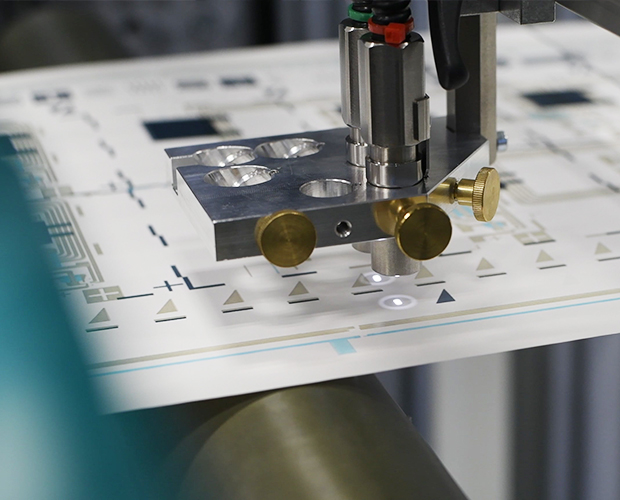

Slot die coating enables full-surface coating of the substrate, which is ideal for barrier or protective layers, while rotary screen printing with a customized screen design can print precise structures in the sub-mm range, such as conductor tracks, capacitors, sensor surfaces or sensor arrays. Depending on the material, curing takes place thermally or by UV exposure using LED technology, with the process being adapted to the temperature stability of the substrate.

Functional elements can be printed on both the top and bottom of the substrate.

The ISO Class 8 cleanroom environment guarantees maximum precision in material coating, which is particularly important for sensitive and extremely thin functional layers. The R2R system is particularly suitable for the production of stretchable dielectric elastomers (DE) and flexible piezopolymer sensors based on PVDF copolymers. Both technologies require the precise printing of several functional layers on top of each other with minimal lateral deviation.

On a screen circumference of 64 cm, either individual, recurring patterns in high quantities or, with a customized screen design, very long functional patterns (up to a maximum substrate length of approx. 200 m) can be printed. Prints can be made up to a width of 40 cm and at printing speeds of up to 4 m/min.

The application of double web edge control guarantees highly precise alignment of the substrate during coating and winding/unwinding, and with the aid of an optical registration and alignment system, the subsequent print can be printed with a lateral deviation of less than 200 µm from the previous one. PET or paper are the preferred substrate materials for cost-effective and efficient production processes.