Mechanical Testing of Polymers

Tabbed contents

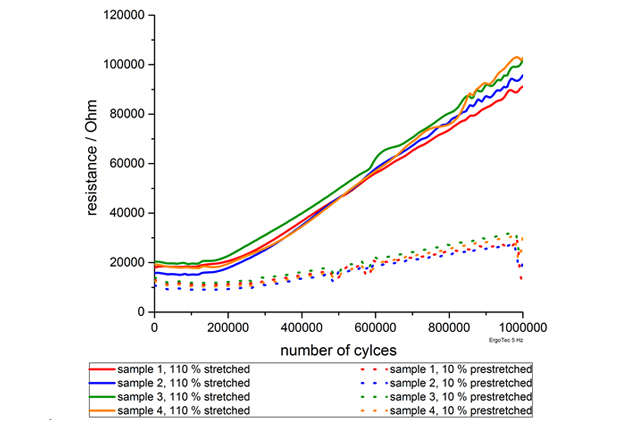

Dynamic Endurance Testing

Dynamic Endurance Testing

Based on classic fatigue tests, CeSMA offers a special fatigue test device that is able to test the mechanical fatigue strength of elastomeric and very soft materials. At the same time, the stability of the electrical resistance of electrically conductive elastomers can be investigated depending on the mechanical load cycles, as a resistance measurement through the sample is integrated into the mechanical clamping. In this way, stretchable conductive lines, resistive sensors or materials used as electrodes in a dielectric elastomer sensor can be characterized electromechanically for their fatigue strength.

The technical specifications of the test device are listed below:

- Up to 8 rubber samples simultaneously: film shaped specimens

- Measurement frequency: 0.1 Hz - 5 Hz

- Stroke-controlled test with wide stroke range: max. 50 – 150 mm

- Dynamic strain: from 1 % towards > 100 %

- Force detection by 8 load cells

- Measurements of conductivity under cyclical linear strain

- Testing up to 10 Million cycles

Tensile Test

Tensile Test

Additional, the quasi-static tensile test (equipped with optical strain measurement for accurate strain detection) is used for determination of

- Tensile strength

- Elongation at break

- Tensile energy

- Modulus of elasticity (Young-modulus)

- Tear strength of polymers

- Mullins effect

Dynamic mechanical analysis (DMA)

Dynamic Mechanical Analysis (DMA)

DMA is used for determination of: glass transmission, softening, storage and loss modulus, Arrhenius-plot

- Measurement mode: strain, compression load, shear stress, bending; relaxation

- Specimen size: thickness 0,05 – 4 mm; width 1 – 12 mm; length 5 – 40 mm

- Stroke range: 5 µm – 300 µm

- Measurement frequency: 0.01 Hz – 100 Hz

- Temperature range: - 100 °C – +500 °C

- Force: max. 8 N