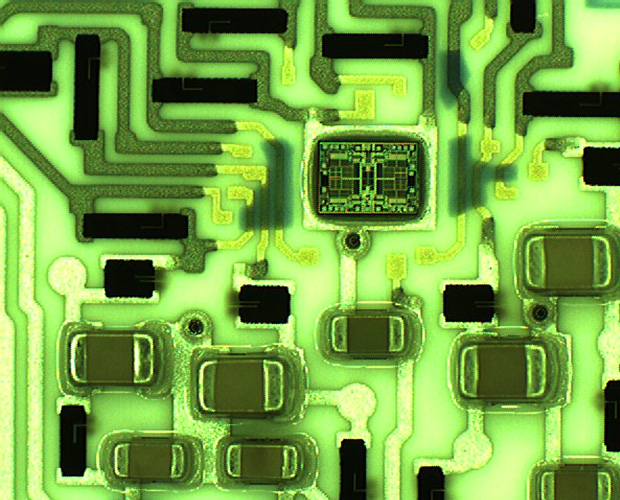

Passivation, thin film encapsulation, and potting materials for electronics

Electronic systems operate more and more in harsh conditions and have to cope with elevated temperatures, corrosive media or – in the field of power electronics – have to handle high currents and voltages.

Inorganic-organic hybrid polymers (ORMOCER®) are versatile material systems that can be used as passivation and encapsulation materials tunable to the respective application. Due to high thermal stability (compared to purely organic encapsulation materials) and chemical inertness, these materials can protect electronic devices and components effectively. Besides, the chemical structure enables a chemical bonding to metallic and metal-oxidic surface. This generates a chemical passivation suppressing formation of dendrites and ionic migration on metal conductors. Additionally, the materials excel by high dielectric strengths (400 V/µm). Finally, some modifications show low water vapor transition rates that protect the electronic device additionally against corrosion.

The materials can be designed as lacquer to be applied via dip-, spin-, or spray-coating or by dispensing.

The materials can also be modified towards silicone-like materials. In this case, the materials are to be used as potting material as well. In all cases, the materials show nice film formation properties. Dual-cure approaches can be implemented on request in order to cure the material fast by UV light and achieve a cross-linking below components in shadowed areas. For special applications, the high optical transparency of the materials can be exploited as well as the adjustment of dielectric permittivity.

For use in biomedical electronic devices, some of the ORMOCER® systems have been tested for biocompatibility and can thus be used in medical applications. In addition, they have proven their stability to sterilization processes. Consequently, ORMOCER®s are promising coating materials for bioelectronic devices.

To date, research is on encapsulation materials that can be used for flexible or even stretchable devices.