Fraunhofer ISC develops materials and technologies for advanced 3D printing.

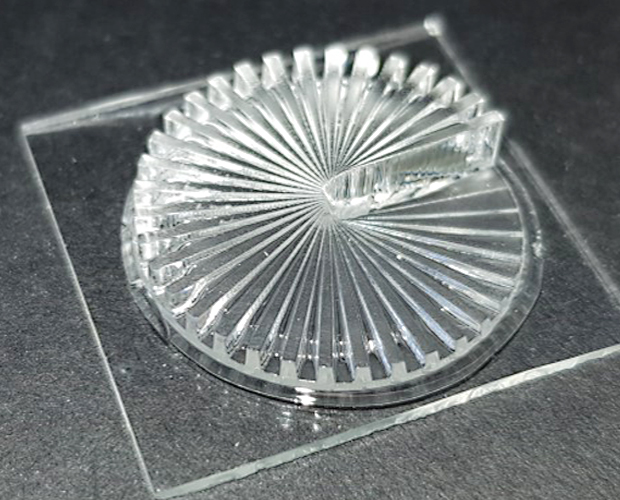

The underlying technology for printing resins and inks are hybrid polymers, which can be tailored towards applications-specific requirements. This so-called ORMOCER® features excellent physical and chemical properties, that go beyond conventional printing materials. ORMOCER® can be formulated to be photopolymerizable. Hence, any light-based printing technology is applicable. Fraunhofer ISC focusses on material and process development for

- Inkjet (3D)-printing

- Stereolithography

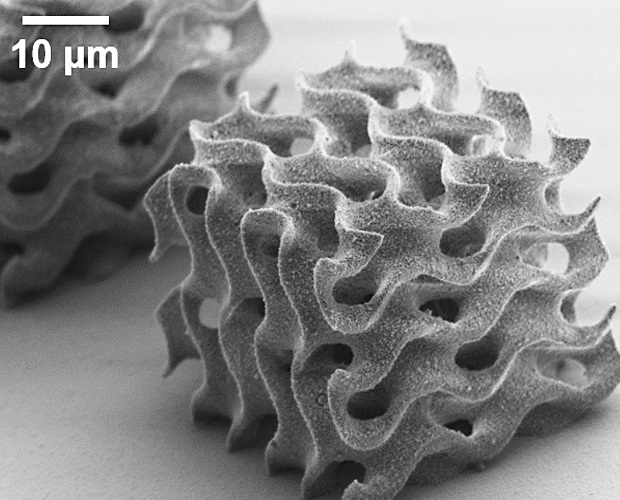

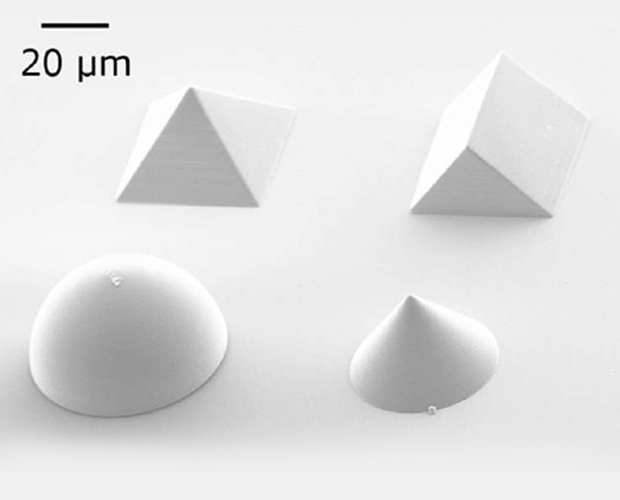

- Two-Photon Polymerization

ORMOCER® can be formulated with nanoparticles to form nanocomposites. These can contain a broad variety of different functional particles, e.g. silica particles to tailor to surface roughness, quantum dots to control the optical emission/absorption of the material, and magnetic nanoparticles.