Fraunhofer ISC can offer unique manufacturing technologies for optics, such as 3D-printing and Two-Photon Polymerization (2PP) to generate light manipulating components for different kinds of optical sensors. These (microoptical) elements could focus, collimate, redirect or distribute light to optimize the performance of the sensor. A tremendous advantage of additive manufacturing technology is the ability to generate different kinds of optical structures directly on the sensor-chip.

Cost-effective color sensors thanks to 2PP

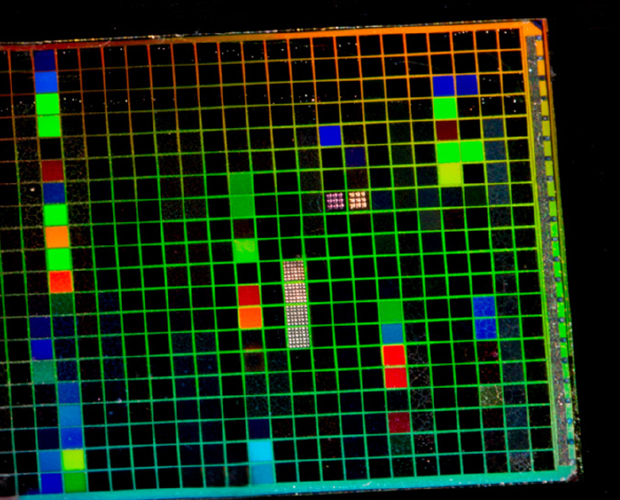

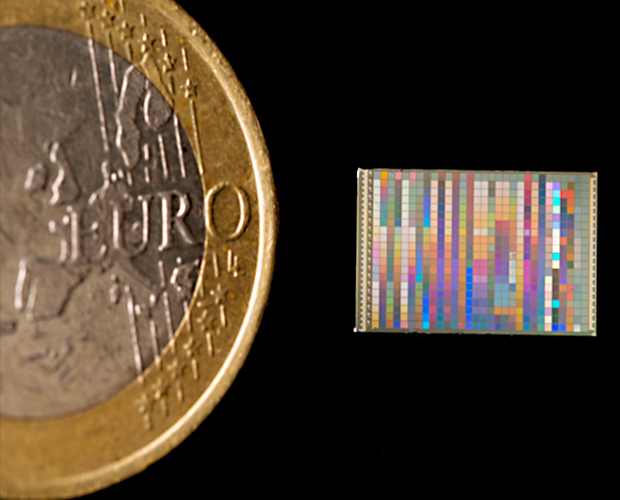

A typical example for a beneficial combination of microoptics manufacturing with 2PP and sensor design is the realization of a low-cost and very compact color sensor. In that example, the sensor relies on plasmonic resonances and is fully manufactured in traditional, hence low-cost, CMOS processing. However, the sensor performance strongly depends on the angle of incidence of the incoming light. Without additional light steering structures, this angular dependence would impede the sensor from working properly. Optical microstructures fabricated directly on top of the CMOS chip could narrow down the angular spectrum of the incoming light in order to enable proper sensor functionality.

Other examples for the lucrative combination of sensor-chips and microoptical components are wavefront-sensors and cameras.