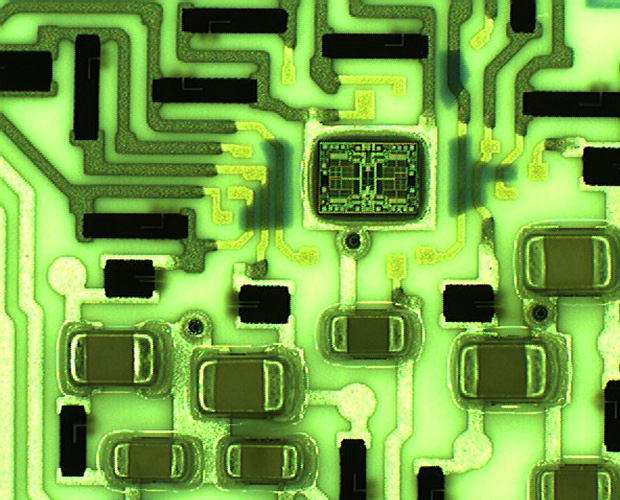

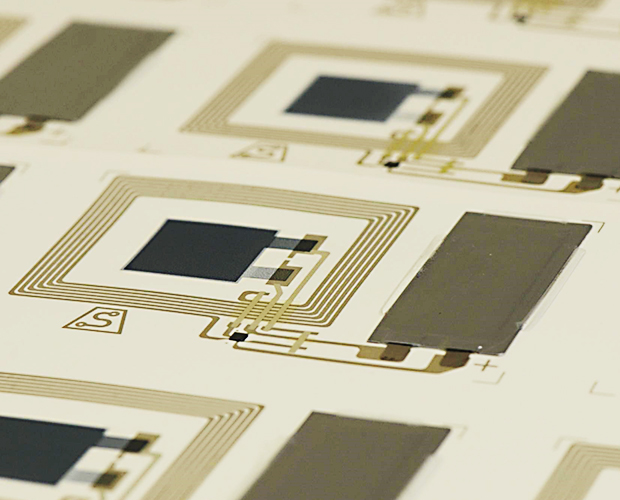

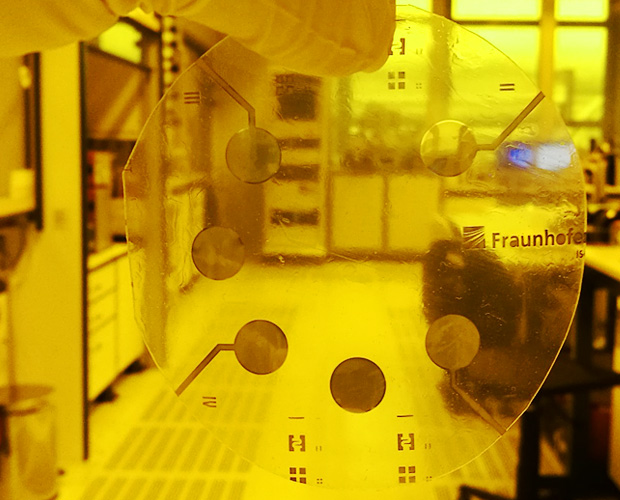

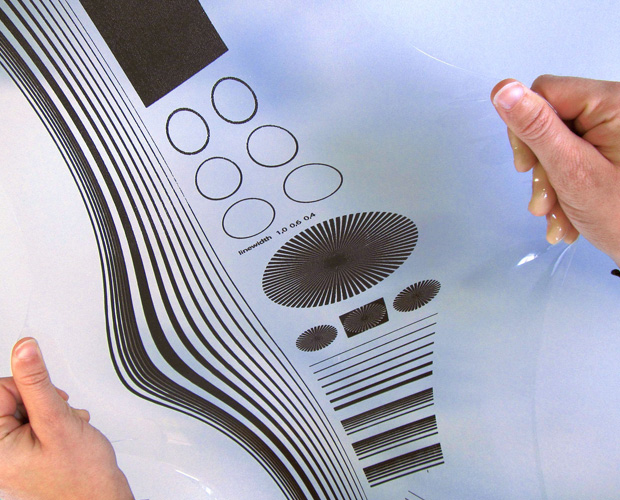

In the last decade, microelectronic components and processes were designed towards the application and were miniaturized, higher integrated, also on unconventional substrates (WLP) and applied in harsher conditions. All materials and processes had to be modified in order to adjust to the new assemblies, processing schemes and application scenarios. Often, thermal stability, encapsulation properties, reliability and performance of conventional used materials do not fulfill the new requirement.

Additionally, power electronics as important component in energy supply systems, ask for high voltage and ampacity that increase the requirement on reliability issues.