(Polymer) Optics

Optical Materials

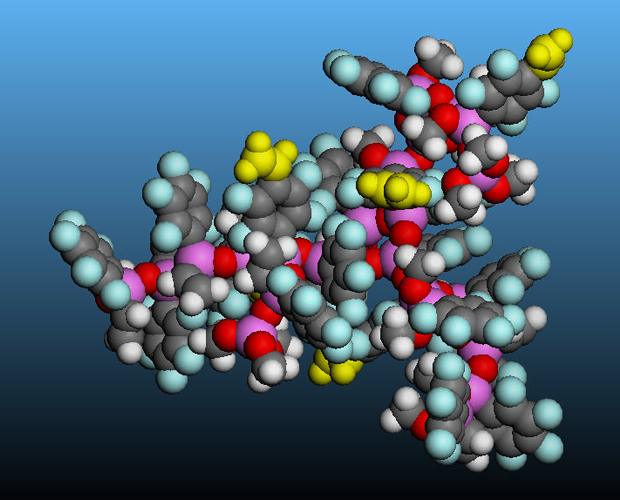

In addition to the processing and development of glasses, Fraunhofer ISC is particularly involved in the development of so-called ORMOCER®s, which are used as material systems for the manufacturing of optical components. These hybrid polymer materials combine the properties of glasses with the processing opportunities of polymers. In addition, ORMOCER®s can be formulated with nanoparticles to form so-called nanocomposites in order to extend the range of properties.

Printed Optics

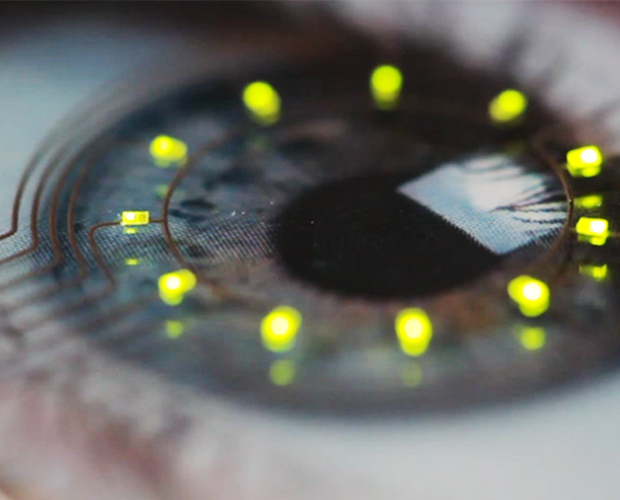

With 3D printing of optics, a class of manufacturing technologies is in the starting blocks that allows the manufacturing of very complex surfaces and thus light distributions without the aid of expensive molding tools or milling processes. Material solutions developed by the ISC make it possible to fully exploit the potential of generative manufacturing processes, especially for individual optics in the field of medical technology (worthwhile from batch size = 1) and for resource-saving production. In addition, additional functionalities (e.g. conductive lines, electro-optical components, absorbing structures, mirrors) can be integrated as desired, so that not only optical components but entire systems can be printed. With inkjet technology and stereolithography, the ISC and its partners offer the necessary hardware platforms for this endeavor.

Printed Microoptics and Microlens-Arrays

In analogy to conventional, "large" optics, microoptical components can be printed using technologies developed at Fraunhofer ISC as well. Two-Photon Polymerization enables the fabrication of diffractive and refractive elements from hybrid polymers on microscopic scales. Typical realization forms are arrays consisting of arbitrarily shaped elements with dimensions between 10 and 100 µm. In principle, Fraunhofer technology can be used to produce microscopic elements of any shape, at any position and on almost any substrate.