Conductive elastomers - Stretchable materials with

electrical conductivity

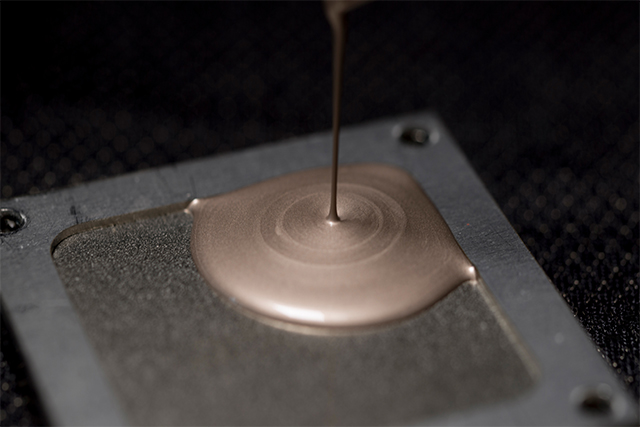

Electrically conductive elastomer compounds can be developed through the targeted incorporation of conductive particles into an elastomer matrix.

Customized conductive silicone elastomers

The Center Smart Materials and Adaptive Systems CeSMA develops conductive silicone elastomers that can be individually adapted to the requirements of a wide range of applications. Not only the electrical conductivity is taken into account, but also the optimal processing and shaping of the materials.

Typical fillers are

- Carbon-based particles (e.g. carbon black, graphite) for moderate conductivity

- Anisotropic metal particles or silver nanowires for high specific conductivities of up to 6,000 S/cm

A particular advantage of our materials is the stability of conductivity even under extreme conditions. This means that the conductivity of our compounds is maintained even at elongations of up to 100 % and under continuous loads of up to 1 million cycles.

Areas of application for conductive elastomers

- Conductive elastomers are used, among other things, as electrode layers in dielectric elastomers. They also enable numerous other applications, including

- Sensor technology: resistive and capacitive sensors for strain or pressure measurement

- Electrostimulation: application on flexible and deformable surfaces

- Medical technology: recording biosignals on the human body

- Flexible electronics: stretchable heating foils and conductor tracks